In today’s fast-paced business landscape, where supply chains span the globe, and customer expectations continue to rise, effective inventory management is more crucial than ever, especially in the realm of cold chain logistics. This is where the role of ERP systems becomes paramount.

Contents

- 1 What is Cold Storage Supply Chain Inventory Management and its Importance

- 2 Benefits of SaaS ERP for Cold Chain Operations

- 3 Cold Supply Chain Integration Challenges with ERP

- 4 Factors to Consider When Evaluating ERP Systems

- 5 Bottom Line

- 6 Frequently Asked Questions (FAQs)

- 6.1 Q1. How can SaaS ERP help reduce inventory holding costs in cold chain logistics?

- 6.2 Q2. Can SaaS ERP be integrated with existing inventory management systems?

- 6.3 Q3. What measures should businesses take to ensure data security in a SaaS ERP environment?

- 6.4 Q4. Can SaaS ERP solutions handle multiple cold chain locations or warehouses?

- 6.5 Q5. How can SaaS ERP improve traceability and compliance in cold chain inventory management?

What is Cold Storage Supply Chain Inventory Management and its Importance

Cold chain inventory management refers to the meticulous control and monitoring of temperature-sensitive goods throughout the supply chain with the help of IoT-enabled sensors. From perishable foods to life-saving pharmaceuticals, maintaining the integrity and quality of products in transit is of utmost importance. By adopting robust cold chain management practices, businesses can minimise waste, ensure regulatory compliance, and safeguard customer satisfaction.

Key Challenges in Cold Chain Inventory Management

- Temperature Control and Monitoring: Maintaining optimal temperature conditions throughout the entire cold chain is a complex challenge. Fluctuations can jeopardise product quality and safety, leading to costly losses.

- Traceability and Compliance: With stringent regulations governing the transportation and storage of temperature-sensitive goods, ensuring traceability and compliance becomes a priority. Failure to meet regulatory requirements can result in severe consequences.

- Inventory Optimisation and Demand Forecasting: Balancing inventory levels with fluctuating demand is a perpetual challenge in cold chain logistics. Accurate demand forecasting and efficient inventory optimisation are essential to prevent stockouts or excess inventory.

- Security Concerns: Temperature-sensitive goods are typically expensive, making them prone to theft or tampering. Adequate security measures must be implemented to protect these items from being stolen or damaged during transportation or storage.

- Integration Issues: Cold chain operations involve a complex network of stakeholders, such as growers, suppliers, distributors, and warehouse operators. The underlying systems must be interoperable and easily integrated to achieve seamless end-to-end traceability for temperature-sensitive goods.

Benefits of SaaS ERP for Cold Chain Operations

- Streamlining Inventory Tracking and Management: SaaS ERP solutions provide real-time visibility into your cold chain inventory, enabling you to track stock levels, monitor expiry dates, and identify slow-moving or obsolete items. This empowers you to make data-driven decisions and optimise your inventory holding.

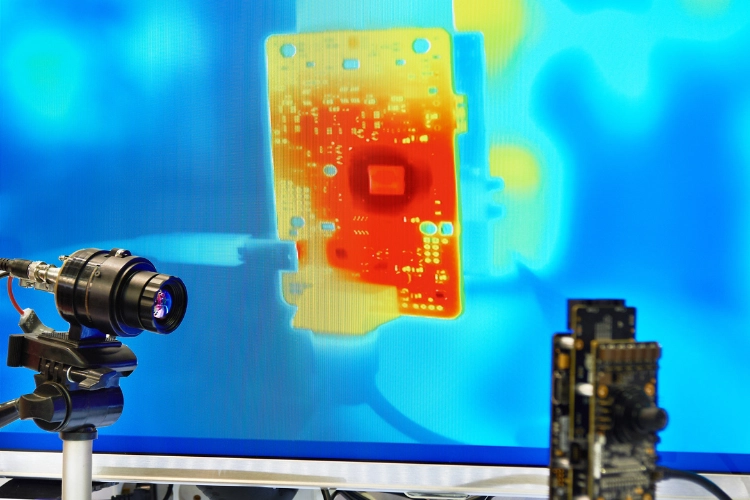

- Real-time Temperature Monitoring and Alerts: With SaaS ERP, you gain access to advanced temperature monitoring capabilities. Integrated sensors and IoT technology ensure that you receive real-time temperature data and alerts, allowing you to take immediate action in case of any deviations.

- Seamless Integration with Supply Chain Partners: SaaS ERP systems offer seamless integration with various stakeholders involved in your cold storage inventory management system, such as suppliers, distributors, and logistics providers. This fosters collaboration, enhances communication, and facilitates smooth end-to-end operations.

- Improved Demand Forecasting: Advanced analytics and predictive algorithms help to forecast demand, allowing you to optimise inventory levels and reduce stockouts accurately.

- Enhanced Security and Compliance: With SaaS ERP solutions, you can be confident that your cold chain operations are compliant with current regulations. Robust security protocols ensure that all data is securely stored and transmitted.

- Reduced Operational Costs: By automating tedious tasks such as inventory tracking and temperature monitoring, SaaS ERP systems can significantly help lower operational costs associated with cold storage logistics management.

Case Studies and Examples

Let’s delve into real-world examples of companies that have successfully implemented SaaS ERP for their cold chain inventory management:

Achieving Seamless Temperature Monitoring and Reporting

A leading pharmaceutical distributor leveraged SaaS ERP to enhance their cold chain operations. By implementing temperature sensors and integrating them with the ERP system, they achieved real-time monitoring of temperature conditions across their distribution network. This enabled them to ensure product quality, comply with regulatory standards, and gain a competitive edge.

Improving Inventory Visibility and Order Fulfillment Efficiency

A frozen food manufacturer faced challenges in inventory visibility and order fulfilment accuracy. They implemented a SaaS ERP solution that provided real-time inventory tracking, demand forecasting, and automated order management. As a result, they achieved higher inventory accuracy, reduced stockouts, and improved on-time delivery performance.

Cold Supply Chain Integration Challenges with ERP

Integrating SaaS ERP with the existing cold storage supply chain management system can present some challenges but can be overcome with careful planning and execution. Consider the following tips:

- Start with a Comprehensive System Evaluation: Understand the strengths and limitations of your existing systems and identify areas that require integration with the SaaS ERP solution. Look for built-in connectors, APIs, or middleware that facilitate smooth data exchange and interoperability. This evaluation will help you develop a clear integration roadmap.

- Choose a Flexible and Customizable ERP Tool: Opt for a SaaS ERP system that offers flexibility and customisation options. This will facilitate seamless integration with your specific business processes and workflows, ensuring a smooth transition.

- Data Mapping and Transformation: Integrating disparate systems often involves mapping and transforming data from one format to another. Identify the data elements required for seamless integration and define mapping rules to ensure accurate and consistent data flow between systems. Leverage tools or integration platforms that support inventory data transformation to simplify this process.

- Testing and Validation: Rigorous testing and validation are critical to ensuring a successful supply chain integration with ERP. Set up test environments that closely resemble your supply chain environment to simulate integration scenarios. Perform end-to-end testing to verify data accuracy, system behaviour, and transactional integrity. Thorough testing minimises the risk of disruptions during the actual integration process.

Ensuring Security in Cold Chain Operations

Security is a top concern for businesses operating in the cold chain. When implementing a SaaS ERP solution, take the following steps to ensure the utmost security:

- Data Encryption and Access Controls: Ensure that your chosen ERP system provides robust data encryption measures to protect sensitive information. Implement access controls to restrict data access based on user roles and permissions.

- Role-Based Access Controls: Implement role-based access controls within the SaaS ERP system to ensure that users can only access data and functionalities relevant to their roles and responsibilities. This granular access control minimises the risk of unauthorised access and protects sensitive information.

- Compliance Certifications: Look for SaaS ERP solutions that comply with industry-specific regulations and standards, such as ISO 27001, for information security management. These certifications demonstrate a commitment to maintaining the highest levels of security.

- Regular Security Audits: Conduct regular security audits to assess the effectiveness of security measures in place. Engage third-party experts to perform comprehensive penetration testing and vulnerability assessments. This proactive approach helps identify potential weaknesses and vulnerabilities, allowing you to address them promptly and enhance overall security.

- Employee Training and Awareness: Promote a culture of security awareness among employees by providing comprehensive training programs. Educate your staff on best practices for data security, password hygiene, and identifying potential security threats such as phishing attempts or social engineering attacks. Regular training sessions ensure that everyone in the organisation remains vigilant and contributes to maintaining a secure environment.

Factors to Consider When Evaluating ERP Systems

When selecting a SaaS ERP solution for your cold chain management needs, keep the following factors in mind:

- Scalability and Customization Options: Scalability comes with Leverage, and Today Leverage comes with SaaS. Ensure that the SaaS ERP system can scale alongside your business growth and adapt to your evolving needs. Customisation options allow you to tailor the solution to match your unique cold chain requirements.

- Cold Chain-Specific Features and Functionality: Look for ERP systems that offer specialised features for cold chain inventory management, such as temperature monitoring, expiry date tracking, and product traceability.

- Integration Capabilities and APIs: Assess the integration capabilities of the ERP solution. It should seamlessly integrate with your existing systems, enabling smooth data flow and communication across your supply chain.

Bottom Line

In conclusion, the role of ERP systems in enhancing cold storage inventory management cannot be overstated. By streamlining inventory tracking, enabling real-time temperature monitoring, addressing integration challenges, and ensuring security, SaaS ERP solutions empower businesses to overcome the complexities of cold chain logistics. With careful evaluation and selection, you can find the right ERP solution to optimise your cold chain operations, increase efficiency, and deliver superior customer experiences.

Frequently Asked Questions (FAQs)

Q1. How can SaaS ERP help reduce inventory holding costs in cold chain logistics?

Answer 1: SaaS ERP systems provide real-time visibility into inventory levels, demand forecasting, and automated replenishment capabilities. By optimising inventory levels and minimising stockouts, businesses can reduce holding costs associated with excess inventory and improve overall supply chain efficiency.

Q2. Can SaaS ERP be integrated with existing inventory management systems?

Answer 2: Yes, It is possible to integrate SaaS ERP with existing inventory management systems. However, it requires careful planning, evaluation of integration capabilities, and customisation options offered by the ERP solution. Working closely with ERP providers and leveraging their expertise will ensure a seamless integration process.

Q3. What measures should businesses take to ensure data security in a SaaS ERP environment?

Answer 3: Data security in a SaaS ERP environment is of utmost importance. Businesses should implement data encryption, access controls based on user roles and permissions, regular data backups, and compliance with industry-specific security standards. Also, choosing a reputable ERP provider with a track record of prioritising data security is crucial.

Q4. Can SaaS ERP solutions handle multiple cold chain locations or warehouses?

Answer 4: Yes, SaaS ERP solutions are designed to handle multiple locations or warehouses. They provide centralised visibility and control over inventory across various sites, enabling businesses to streamline operations, optimise stock levels, and efficiently manage inventory movement between different cold chain locations.

Q5. How can SaaS ERP improve traceability and compliance in cold chain inventory management?

Answer 5: SaaS ERP solutions offer advanced traceability features like product serialisation, batch tracking, and expiry date management. By capturing and recording crucial information at every stage of the cold chain, businesses can achieve end-to-end traceability, ensuring compliance with regulatory requirements. This improves product recall capabilities, facilitates quality control, and enhances customer trust.